Professional vs. DIY Installation

When considering gas line installation and repair, many homeowners weigh the option of hiring a professional versus tackling the project themselves. Professional plumbers and gas fitters bring expertise and experience to the table, ensuring that the installation meets local codes and operates safely. They can navigate complex regulations and provide peace of mind through warranty options, which may be necessary for larger projects or those involving extensive installations.

On the other hand, a DIY approach can be appealing for those with handyman skills and a desire to save money. Homeowners who choose to install a gas line themselves should be aware of the risks involved and must thoroughly research local regulations. Proper planning and knowledge of the materials needed are essential. If safety protocols are overlooked, the consequences can be severe.

Pros and Cons of Each Approach

When considering gas line installation and repair, opting for a professional approach generally ensures safety and compliance with local codes. Licensed technicians bring extensive knowledge and experience to the table, minimizing the risk of errors. They can navigate permitting processes and conduct inspections effectively. However, this level of service comes at a higher cost, which some homeowners might find prohibitive.

On the other hand, a DIY installation can save money upfront and allow for greater control over the project timeline. Homeowners with plumbing or construction experience may find it fulfilling to take on this challenge. Nonetheless, without proper knowledge, the likelihood of mistakes increases. These errors can lead to safety hazards or costly repairs, undermining any initial savings. Understanding the intricacies of gas line systems is essential for a successful installation.

Cost Involved in Running a Gas Line

The cost involved in running a gas line can vary significantly based on several factors, including the length of the line, the complexity of the installation, and local labor rates. Homeowners should expect to spend anywhere from several hundred to several thousand dollars. This range covers materials, labor, permits, and potential inspections required by local authorities. Gas line installation and repair necessitate adherence to building codes, which can further impact the overall expense.

Additionally, specific materials and components can influence costs. For example, black iron pipe is a common choice for gas lines, but its price fluctuates based on market conditions. If any trenching or additional excavation is necessary, these factors will also contribute to the total cost. Be sure to obtain multiple quotes from licensed professionals to ensure a fair price for the work required.

Breakdown of Expenses

When considering the expenses associated with running a gas line to your home, it's crucial to evaluate various cost components. Gas line installation and repair costs can vary significantly based on the length of the line, the type of gas being used, and local regulations. Homeowners should anticipate initial expenses for materials such as piping and fittings, along with labor costs if hiring professionals. Depending on the scope of the project, additional fees may arise from securing permits or conducting inspections.

In terms of budget planning, it's advisable to gather multiple quotes from licensed contractors to ensure transparency and competitiveness in pricing. Always factor in potential unforeseen costs, such as repairs to landscaping, sidewalks, or other areas disturbed during installation. Investing in proper equipment and ensuring all safety measures are in place can prevent additional expenses down the line, making the initial outlay worthwhile.

Choosing the Right Equipment

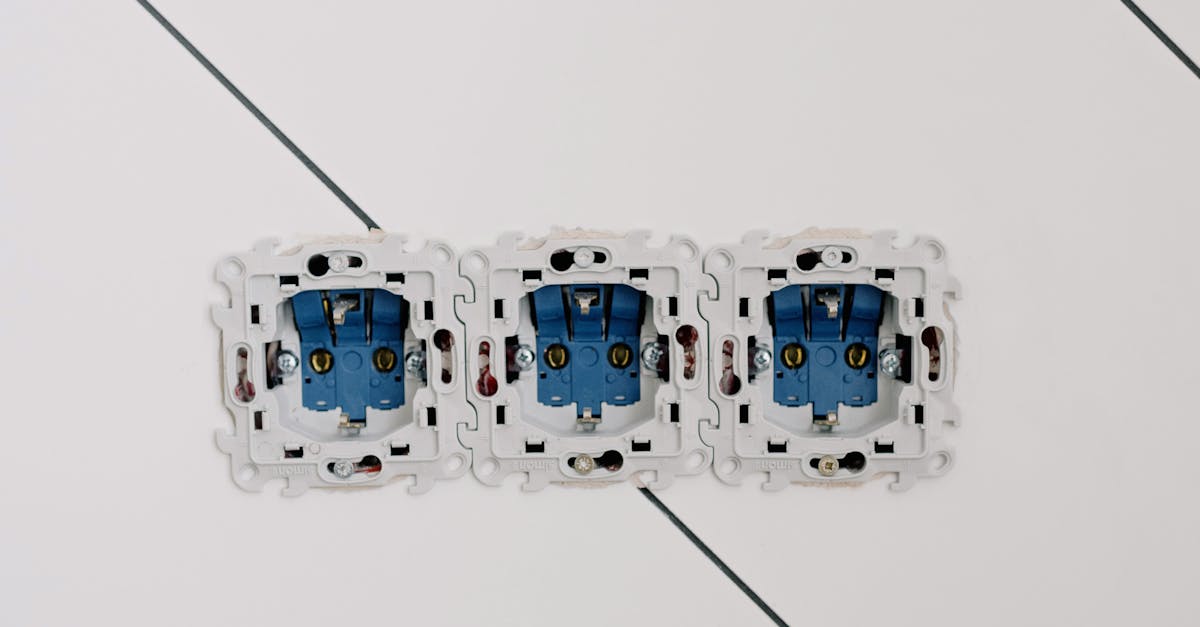

Selecting the right equipment for gas line installation and repair is crucial for ensuring safety and efficiency. Begin by identifying high-quality materials such as gas-rated pipes and fittings. These components are designed to withstand pressure and resist corrosion, which is important for long-term reliability. Always opt for materials that meet the standards set by local building codes. Using inferior products can lead to leaks or system failures, jeopardizing safety.

In addition to materials, having the right tools is essential for the installation process. Basic tools include pipe wrenches, a pipe cutter, and Teflon tape. Advanced installations may require specialty tools like gas detectors and pressure testing equipment. Investing in the right equipment not only simplifies the installation process but also helps in maintaining the integrity of the gas line over time. Proper equipment ensures compliance with safety regulations and facilitates efficient troubleshooting if repairs are needed in the future.

Essential Tools and Materials Needed

For gas line installation and repair, having the right tools and materials is crucial for ensuring safety and efficiency. Basic tools include a pipe wrench, adjustable wrenches, and a level. A tubing cutter is essential for making precise cuts on the gas pipe. Additionally, a gas leak detector can help identify potential leaks, providing peace of mind throughout the process. Personal protective equipment such as gloves and safety goggles should also be part of your toolkit to ensure safety while working.

The materials required will depend on the specific project needs, but common items include gas piping, fittings, and valves. Depending on local codes, you may also need specialized sealants or compounds to ensure secure connections. Choosing the correct pipe material—such as black iron or corrugated stainless steel—also plays a significant role in determining the line's safety and longevity. Gathering all necessary tools and materials before starting the project can streamline the installation and minimize interruptions.

FAQS

Can I run a gas line to my house myself?

While it is possible to run a gas line yourself, it is highly recommended to hire a professional due to safety concerns and local regulations.

What are the pros of hiring a professional for gas line installation?

Hiring a professional ensures that the installation is done safely, adheres to local codes, and minimizes the risk of leaks or other hazards.

How much does it typically cost to install a gas line?

The cost of installing a gas line can vary widely depending on the distance from the main line, local labor rates, and the complexity of the installation, but it often ranges from $500 to $2,000.

What essential tools do I need for a DIY gas line installation?

Essential tools for a DIY installation may include a pipe wrench, Teflon tape, pipe cutters, a gas leak detector, and necessary fittings, although it's best to consult a professional for a complete list.

Are there any permits required for running a gas line?

Yes, most localities require permits for gas line installations to ensure compliance with safety codes, so it's important to check with your local building department before starting the project.